Bonnet hinge modification

- Glyn Ruck

- Posts: 1619

- Joined: Sun Oct 07, 2018 2:14 pm

- Location: Llandudno, Cape Town, South Africa

- Contact:

Re: Bonnet hinge modification

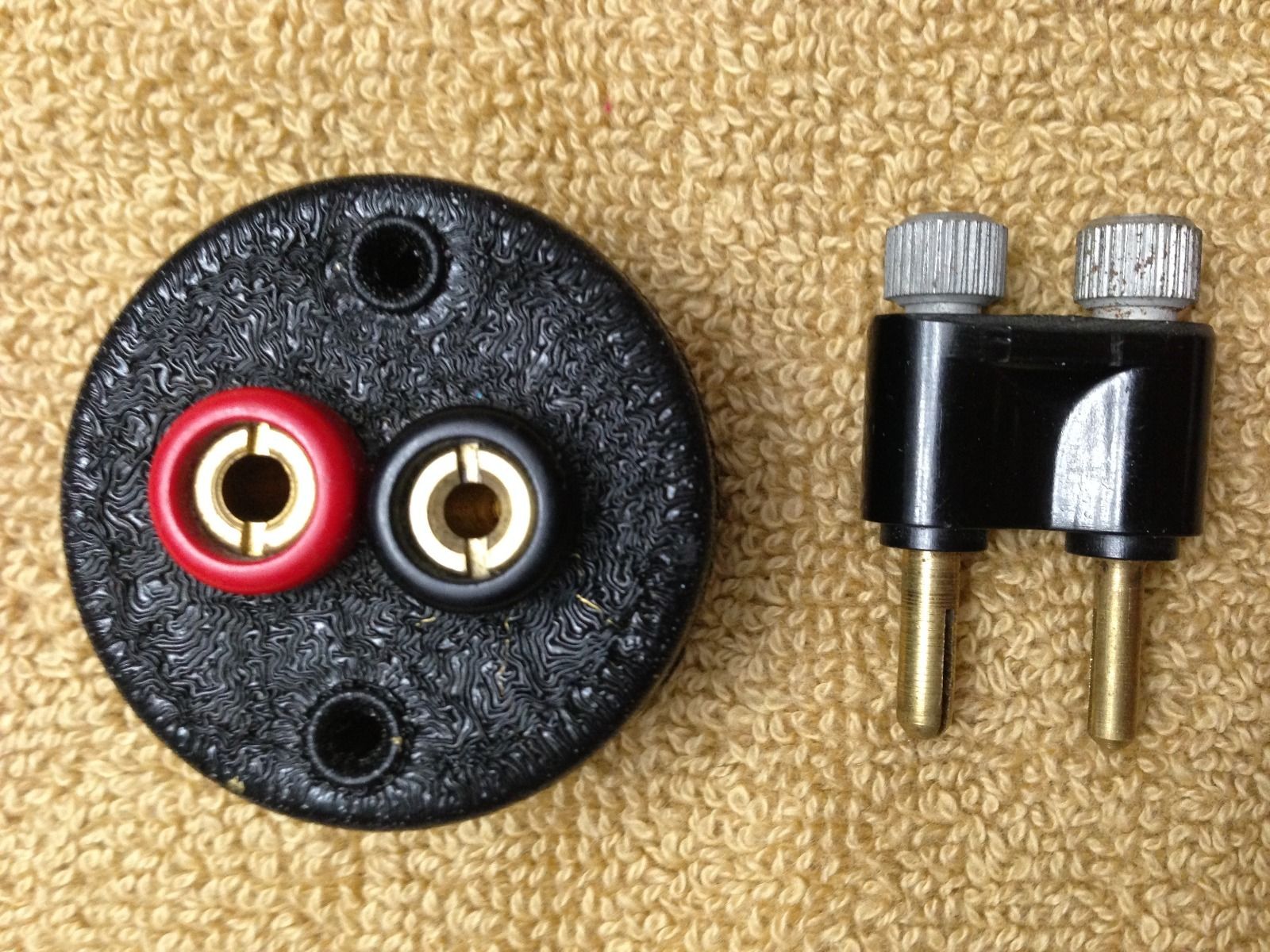

Does anybody have any ideas as to how to get the wrinkle finish onto this socket like Lucas did? I've tried & failed.

1965 Jaguar 3.8 S Type, Sync4, OD, PAS, BRG/Biscuit on chrome wires.

http://www.jagstyperegister.com/forum_n ... ?f=3&t=152

A1B56966DN

http://www.jagstyperegister.com/forum_n ... ?f=3&t=152

A1B56966DN

Re: Bonnet hinge modification

Glyn MG used to paint their dash fronts with a black crinkle/wrinkle paint like this.

Have a look at this article https://www.mgexp.com/article/wrinkle-paint.html

Moss do what they call a crackle paint at https://www.moss-europe.co.uk/paint-cra ... 1048a.html

Have a look at this article https://www.mgexp.com/article/wrinkle-paint.html

Moss do what they call a crackle paint at https://www.moss-europe.co.uk/paint-cra ... 1048a.html

Rob.C. P1B8973BW

1968 S Type 3.4 Auto. Old English White.

1993 Yamaha FJ1200 Yellow

1966 Ford Anglia 1760 cross flow (still being built)

2012 Old English sheep dog. Grey and white.

http://torbayweddingcarclub.co.uk/?page_id=57

1968 S Type 3.4 Auto. Old English White.

1993 Yamaha FJ1200 Yellow

1966 Ford Anglia 1760 cross flow (still being built)

2012 Old English sheep dog. Grey and white.

http://torbayweddingcarclub.co.uk/?page_id=57

- Glyn Ruck

- Posts: 1619

- Joined: Sun Oct 07, 2018 2:14 pm

- Location: Llandudno, Cape Town, South Africa

- Contact:

Re: Bonnet hinge modification

Thanks Rob. That is much better than I have achieved. That Lucas paint has a very defined wrinkle. Don't know how it was done.

1965 Jaguar 3.8 S Type, Sync4, OD, PAS, BRG/Biscuit on chrome wires.

http://www.jagstyperegister.com/forum_n ... ?f=3&t=152

A1B56966DN

http://www.jagstyperegister.com/forum_n ... ?f=3&t=152

A1B56966DN

Re: Bonnet hinge modification

Rob

I have been interested in increasing the bonnet opening angle for some time and therefore very interested in your work to date. Thank you for your efforts so far and your willingness to share your findings which I found to be helpful.

I realised from the beginning that it is impossible to merely remove one rivet or bolt to open up the bonnet aperture. To increase the bonnet opening angle at least one of the links on each hinge must be modified. If the owner is prepared for a modification all is well, if not read no more!

In that respect I would like to make some suggestion and comment. However, I would like to make it clear, that I am at no time suggesting my comments are a complete fix for a bonnet hinge modification without some more work.. The comment is what I see from jury rigging two hinge assemblies and I am interested in any constructive comment. It may be that none of my comment is of use, as I have not yet been able to mount and check a modified hinge on the car. In fact it will be a considerable time before I can do so.

I see that you experienced the rear bonnet edge fouling the heater and I started by trying to eliminate that situation. To prevent any chance of fouling the heater or windscreen valance it is necessary to raise the rear of the bonnet to its highest point. This entails ensuring that the rear link, (that is the one onto which the spring hooks) only moves to a vertical position and no further. Taking dimensions from my jigged hinge I think the bonnet will just clear the scuttle in that position. To achieve that situation a stop must be fitted, this actually is the opposite to what you did at your “lower bracket stopper”.

The stop can be made in a number of ways, from drilling a hole and fitting a removable plug to a gravity operated catch. Whatever method is used it is very advantageous to utilise a stop system that can be put into or out of action. The upper hinge frame to inner wing bolt makes an ideal anchor point to mount a gravity stop.

However, fitting a stop to gain the highest position for the rear link on its own, then limits the bonnet opening to 20 degrees, unless a modification is done to the (175mm centres) front link. This is enough for oil level checks etc, but little more. To overcome the front link issue I replaced it with a stainless steel turnbuckle.

For those not familiar with turnbuckles these are threaded left hand at one end and right hand at the other, such that when turning the centre tube the turnbuckle will expand or contract in length. I used one that would just expand its centres from a “closed bonnet” position of 175 mm centres to an “open bonnet “situation” of 250 mm centres.

Once fitted in place of the front link the turnbuckle can be left at 175 mm centres and without the rear link stop in position the bonnet will open as normal. On the contrary the turnbuckle can be unscrewed alternatively on each hinge to 240 mm centres, when the hinge / bonnet opening is approximately 95 degrees. I believe from my jury rigged hinge that the bonnet will clear the rear opening where the rubber water strip sits above the starter solenoid.

Even if this arrangement did not clear the scuttle at the rear the gain in possible bonnet opening would be advantageous. I realise that owners will not want to be continually using the turnbuckles, but as previously described, the arrangement can be set in the standard position with the need to operate the turnbuckles only when extra opening is required.

To date I have used turnbuckles to assess the situation and be able to quickly find the necessary closed and open attachment pin centre lengths. It has occurred to me that a gas strut could take the place of my turnbuckles as these require manual operation if a wide bonnet access is required, but that can be done quickly with a small tommy bar.

The diameter of any gas strut is critical as it would run extremely close to the main spring and the end attachment style would need thought….perhaps small ball joints. Currently the end fittings on my turnbuckles are fork ends trimmed of one arm to form an L shape, mounting clevises are 8 mm whilst the brackets are the original 10mm. These sizes would be synchronised if the idea was progressed.

A

s an alternative to the above method it should be possible to make up a sliding extension link to lengthen the front link as the bonnet is opened. This link could be designed like a knife scabbard so that one section would slide in the other with a bolt to clamp the arrangement at the open position.

In any instance the rear link must be prevented from going past the vertical position and the front link must be capable of lengthening from 175 mm to 250 mm, if the opening is to be increased. If an owner is satisfied with as much opening as possible without incorporating a rear stop, then the front link could just be replaced with a turnbuckle.

Currently I am awaiting delivery of some small gas struts and I may also try the scabbard idea. I would like to try the present hinge arrangement to ascertain if the turnbuckle hinge will allow scuttle clearance.

If you are interested you can loan my existing turnbuckles for a couple of weeks.

Norman

I have been interested in increasing the bonnet opening angle for some time and therefore very interested in your work to date. Thank you for your efforts so far and your willingness to share your findings which I found to be helpful.

I realised from the beginning that it is impossible to merely remove one rivet or bolt to open up the bonnet aperture. To increase the bonnet opening angle at least one of the links on each hinge must be modified. If the owner is prepared for a modification all is well, if not read no more!

In that respect I would like to make some suggestion and comment. However, I would like to make it clear, that I am at no time suggesting my comments are a complete fix for a bonnet hinge modification without some more work.. The comment is what I see from jury rigging two hinge assemblies and I am interested in any constructive comment. It may be that none of my comment is of use, as I have not yet been able to mount and check a modified hinge on the car. In fact it will be a considerable time before I can do so.

I see that you experienced the rear bonnet edge fouling the heater and I started by trying to eliminate that situation. To prevent any chance of fouling the heater or windscreen valance it is necessary to raise the rear of the bonnet to its highest point. This entails ensuring that the rear link, (that is the one onto which the spring hooks) only moves to a vertical position and no further. Taking dimensions from my jigged hinge I think the bonnet will just clear the scuttle in that position. To achieve that situation a stop must be fitted, this actually is the opposite to what you did at your “lower bracket stopper”.

The stop can be made in a number of ways, from drilling a hole and fitting a removable plug to a gravity operated catch. Whatever method is used it is very advantageous to utilise a stop system that can be put into or out of action. The upper hinge frame to inner wing bolt makes an ideal anchor point to mount a gravity stop.

However, fitting a stop to gain the highest position for the rear link on its own, then limits the bonnet opening to 20 degrees, unless a modification is done to the (175mm centres) front link. This is enough for oil level checks etc, but little more. To overcome the front link issue I replaced it with a stainless steel turnbuckle.

For those not familiar with turnbuckles these are threaded left hand at one end and right hand at the other, such that when turning the centre tube the turnbuckle will expand or contract in length. I used one that would just expand its centres from a “closed bonnet” position of 175 mm centres to an “open bonnet “situation” of 250 mm centres.

Once fitted in place of the front link the turnbuckle can be left at 175 mm centres and without the rear link stop in position the bonnet will open as normal. On the contrary the turnbuckle can be unscrewed alternatively on each hinge to 240 mm centres, when the hinge / bonnet opening is approximately 95 degrees. I believe from my jury rigged hinge that the bonnet will clear the rear opening where the rubber water strip sits above the starter solenoid.

Even if this arrangement did not clear the scuttle at the rear the gain in possible bonnet opening would be advantageous. I realise that owners will not want to be continually using the turnbuckles, but as previously described, the arrangement can be set in the standard position with the need to operate the turnbuckles only when extra opening is required.

To date I have used turnbuckles to assess the situation and be able to quickly find the necessary closed and open attachment pin centre lengths. It has occurred to me that a gas strut could take the place of my turnbuckles as these require manual operation if a wide bonnet access is required, but that can be done quickly with a small tommy bar.

The diameter of any gas strut is critical as it would run extremely close to the main spring and the end attachment style would need thought….perhaps small ball joints. Currently the end fittings on my turnbuckles are fork ends trimmed of one arm to form an L shape, mounting clevises are 8 mm whilst the brackets are the original 10mm. These sizes would be synchronised if the idea was progressed.

A

s an alternative to the above method it should be possible to make up a sliding extension link to lengthen the front link as the bonnet is opened. This link could be designed like a knife scabbard so that one section would slide in the other with a bolt to clamp the arrangement at the open position.

In any instance the rear link must be prevented from going past the vertical position and the front link must be capable of lengthening from 175 mm to 250 mm, if the opening is to be increased. If an owner is satisfied with as much opening as possible without incorporating a rear stop, then the front link could just be replaced with a turnbuckle.

Currently I am awaiting delivery of some small gas struts and I may also try the scabbard idea. I would like to try the present hinge arrangement to ascertain if the turnbuckle hinge will allow scuttle clearance.

If you are interested you can loan my existing turnbuckles for a couple of weeks.

Norman

Re: Bonnet hinge modification

Thanks for the suggestions Norman. As the weather is warm I have been working on this for a couple of days now.

I think lengthening the front arm only makes the back of the bonnet drop and come into contact with the top of the heaterso you are right about lengthening the the rear arm at the same time to raise the bonnet. It is getting the angles correct and is not easy.

At the moment I am working on a different set of hinge lever arms with an additional bracket. Looking at the bonnet what you require is for the initial lift of the bonnet to not only lift the front but to also lift the back lip of the bonnet up in the air or slide it forwards otherwise the back lip of the bonnet will connect with the weather strip and scuttle. I have a set of BMW hinges with gas struts which operate in the correct angles but trying to them get these attached to the Jaguar inner wings creates a problem.

I have a friend who can plasma cut 5mm steel so I made up some drawings for a plate based on the angles of the BMW hinge and the Jaguar body but before I had them cut I made some up out of Plyboard and did a trial fit. These did not work (Too big) so I have just spent all day trimming and cutting to try and get these to fit. The thing is you need to use the Jaguar bracket that sits against the inner wing and the "L" shaped bracket that bolts to the underside of the bonnet and what goes in between has to line them up correctly. The other thing is there is not a lot of room on the left side (Passengers side for UK vehicles) because of the heater box. I would also like the hinge to use the original springs rather than struts so it looks fairly original other than it lifts up to 90 degrees.

Believe me it is not easy and the number of times I thought I had it but then something would get in the way and I have yet to even try fitting the bonnet to my new hinge design.

So at the moment what I am looking at is a plate that sits between the Jaguar inner wing bracket and a new set of lever arms that attach to the "L" shaped bracket that in turn attaches to the bonnet. The plate lifts the starting point of the lever arms up meaning the bonnet lifts as it should off the back of the weather strip initially but then is able to go beyond 90 degrees without the back fouling the heater. The tricky bit here is not getting the bonnet up but to get it to sit back down flat without the new lever arms getting in the way.

I will let you know how I get on with pictures over the next couple of days.

I think lengthening the front arm only makes the back of the bonnet drop and come into contact with the top of the heaterso you are right about lengthening the the rear arm at the same time to raise the bonnet. It is getting the angles correct and is not easy.

At the moment I am working on a different set of hinge lever arms with an additional bracket. Looking at the bonnet what you require is for the initial lift of the bonnet to not only lift the front but to also lift the back lip of the bonnet up in the air or slide it forwards otherwise the back lip of the bonnet will connect with the weather strip and scuttle. I have a set of BMW hinges with gas struts which operate in the correct angles but trying to them get these attached to the Jaguar inner wings creates a problem.

I have a friend who can plasma cut 5mm steel so I made up some drawings for a plate based on the angles of the BMW hinge and the Jaguar body but before I had them cut I made some up out of Plyboard and did a trial fit. These did not work (Too big) so I have just spent all day trimming and cutting to try and get these to fit. The thing is you need to use the Jaguar bracket that sits against the inner wing and the "L" shaped bracket that bolts to the underside of the bonnet and what goes in between has to line them up correctly. The other thing is there is not a lot of room on the left side (Passengers side for UK vehicles) because of the heater box. I would also like the hinge to use the original springs rather than struts so it looks fairly original other than it lifts up to 90 degrees.

Believe me it is not easy and the number of times I thought I had it but then something would get in the way and I have yet to even try fitting the bonnet to my new hinge design.

So at the moment what I am looking at is a plate that sits between the Jaguar inner wing bracket and a new set of lever arms that attach to the "L" shaped bracket that in turn attaches to the bonnet. The plate lifts the starting point of the lever arms up meaning the bonnet lifts as it should off the back of the weather strip initially but then is able to go beyond 90 degrees without the back fouling the heater. The tricky bit here is not getting the bonnet up but to get it to sit back down flat without the new lever arms getting in the way.

I will let you know how I get on with pictures over the next couple of days.

Rob.C. P1B8973BW

1968 S Type 3.4 Auto. Old English White.

1993 Yamaha FJ1200 Yellow

1966 Ford Anglia 1760 cross flow (still being built)

2012 Old English sheep dog. Grey and white.

http://torbayweddingcarclub.co.uk/?page_id=57

1968 S Type 3.4 Auto. Old English White.

1993 Yamaha FJ1200 Yellow

1966 Ford Anglia 1760 cross flow (still being built)

2012 Old English sheep dog. Grey and white.

http://torbayweddingcarclub.co.uk/?page_id=57

Re: Bonnet hinge modification

ROB

I hope I am successful in posting these images. One shows the turnbuckle centres at 175mm, identical to the original front link centres. In this situation I have used a bolt for a temporary stop for the rear link to stay vertical. Note the assembly is tilted in the image but the rear link is actually vertical.

The second image shows the turnbuckle at 245 mm centres still with the temporary stop fitted.

I understand your finding in regard to the problem of fouling the heater. I think you will find that if you retain the rear link at the vertical position not only is the bonnet raised but importantly it is held to the rear and appears to me to have a chance of missing the scuttle drain channel. I will look forward to your experiments, I would like to see the bonnet opening improved for sure.

One advantage of using the turnbuckles is that they can be adjusted at any time and that makes it more convenient than fixed links especially for experimental purposes

I hope I am successful in posting these images. One shows the turnbuckle centres at 175mm, identical to the original front link centres. In this situation I have used a bolt for a temporary stop for the rear link to stay vertical. Note the assembly is tilted in the image but the rear link is actually vertical.

The second image shows the turnbuckle at 245 mm centres still with the temporary stop fitted.

I understand your finding in regard to the problem of fouling the heater. I think you will find that if you retain the rear link at the vertical position not only is the bonnet raised but importantly it is held to the rear and appears to me to have a chance of missing the scuttle drain channel. I will look forward to your experiments, I would like to see the bonnet opening improved for sure.

One advantage of using the turnbuckles is that they can be adjusted at any time and that makes it more convenient than fixed links especially for experimental purposes

- Attachments

-

- Centres at 245 mm.JPG (1.58 MiB) Viewed 2850 times

-

- Centres at 175mm.JPG (1.6 MiB) Viewed 2850 times

Re: Bonnet hinge modification

The turnbuckles are a good idea but you would have to add one to the rear lever arm otherwise you will have exactly the same problem I had with just removing the stopper rivet. The back of the bonnet in the photos you have shown would I guarantee hit the heater box. The back lever arm has to be longer but by doing so you will find the bonnet will not sit on the weather strip when you close it. I know as I have tried all this and it is not obvious until you actually bolt the hinge in position and take measurements.

I have now achieved getting the angles correct and it is a case of adjusting the pivot point of the rear lever arm whilst lengthening the front arm. As I said I think I have got it now after 10 hours of experimenting but I will make up a new bracket tomorrow add the holes and offer it up. I will then post some photos.

I have now achieved getting the angles correct and it is a case of adjusting the pivot point of the rear lever arm whilst lengthening the front arm. As I said I think I have got it now after 10 hours of experimenting but I will make up a new bracket tomorrow add the holes and offer it up. I will then post some photos.

Rob.C. P1B8973BW

1968 S Type 3.4 Auto. Old English White.

1993 Yamaha FJ1200 Yellow

1966 Ford Anglia 1760 cross flow (still being built)

2012 Old English sheep dog. Grey and white.

http://torbayweddingcarclub.co.uk/?page_id=57

1968 S Type 3.4 Auto. Old English White.

1993 Yamaha FJ1200 Yellow

1966 Ford Anglia 1760 cross flow (still being built)

2012 Old English sheep dog. Grey and white.

http://torbayweddingcarclub.co.uk/?page_id=57

Re: Bonnet hinge modification

OK this is way more complicated than I thought.

My intention was just to get the bonnet/hood to rise above 45 degrees so if I was working on anything at the back of the engine bay I would not have to remove the bonnet/hood.

Trial one was to remove the stopper rivet leaving everything else as stock. This in theory allowed the bonnet/hood to rise to 90 degrees. Problem was the back of the bonnet/hood drops as the hinge rotates and the back of the bonnet/hood fouled against the heater box stopping it from rising.

I sat and studied the original hinge and drew some diagrams as to how it worked. When the front of the bonnet/hood is lifted the back of the bonnet/hood also lifts to clear the weather strip on the scuttle. Next the rear of the bonnet/hood rotates forward as it lifts increasing the gap between the weather strip and the back edge. Lastly the hinge rotates the bonnet/hood up pushing the rear edge down into the engine compartment. As it rises to 45 degrees there is a rivet that stops the bonnet/hood rising any further at the front but also stops the rear edge dropping further into the engine bay and hitting the heater box. What is required are longer arms to lift the bonnet/hood but are still able to fold in to the gap when closed

There was no way you could use the original hinge to get the result required because of the rotational angles it creates and the length of the arms.

I had a set of BMW hinges which worked in a similar fashion but allowed the hinge to lift the bonnet/hood up to 90 degrees so I studied they way they worked. They work with a ram rather than a spring and were almost flush fit so getting them to fit the Jaguar inner wing was a problem. I really wanted to keep the look of the Jaguar hinge if possible and use the spring which I will come to later rather than a modern hydraulic ram. I removed all the rivets holding the Jaguar hinge together and repeated this with the BWM hinge and to cut a long story short I used the mechanical arms of the BMW with the top plate and inner wing plate of the Jaguar to try and get a rotational hinge that worked.

I used a cardboard sheet to map the rotation of the hinges using different reference holes when the hinge plate was in place to get the right lift and rotation. You can see the difference between the original hing on the bottom and how I was able to lift the hing in the top diagram. I made an extra plate that bolted to the inner wing plate of the Jaguar out of ply board which allowed me to play around with different hole positions for the arms. A couple of days later and after lots of adjustment I thought I had the perfect set up and offered it up to the car. I made a template of the back edge of the bonnet/hood out of plastic which allowed me to use the hinge and see if I had all the correct heights and rotation then I fitted both hinges and the bonnet/hood. All seemed to work so I made the plate out of some 3mm steel I had lying around and then considered how I was going to fit the spring.

The thing with the spring on the original set up is that it allows the bonnet/hood to be lifted with assistance. The spring is stretched as the bonnet/hood is closed and contracts as it lifts but it also cleverly holds enough tension in the closed position to hold the back of the hinge down against the weather strip. I tried to fit the spring in the same orientation as the original but found two things. If it was not set correctly it would not hold the back edge of the bonnet down on the weather strip and if you got it slightly wrong the other way the back of the bonnet/hood would not lift when you opened the front edge up. I looked at using the hydraulic ram but with this in the correct position to push the bonnet/hood open it also tried to push the back edge up when the front was closed down. The ram was not going to work.

I am now working on a way of getting the spring to do as it should using levers attached to the levers. All very fiddly and possibly a lot easier to do these days on a 3D CAD program which I do not have rather than trial and error which is what I am using.

I am of the opinion at the moment that it would have been easier to have redesigned the heater box so the back could drop into the engine bay without fouling it than redesign the hinge.

Still working on it along with other things but the way it looks at the moment I would defy anyone to try and copy what I have done so far.

My intention was just to get the bonnet/hood to rise above 45 degrees so if I was working on anything at the back of the engine bay I would not have to remove the bonnet/hood.

Trial one was to remove the stopper rivet leaving everything else as stock. This in theory allowed the bonnet/hood to rise to 90 degrees. Problem was the back of the bonnet/hood drops as the hinge rotates and the back of the bonnet/hood fouled against the heater box stopping it from rising.

I sat and studied the original hinge and drew some diagrams as to how it worked. When the front of the bonnet/hood is lifted the back of the bonnet/hood also lifts to clear the weather strip on the scuttle. Next the rear of the bonnet/hood rotates forward as it lifts increasing the gap between the weather strip and the back edge. Lastly the hinge rotates the bonnet/hood up pushing the rear edge down into the engine compartment. As it rises to 45 degrees there is a rivet that stops the bonnet/hood rising any further at the front but also stops the rear edge dropping further into the engine bay and hitting the heater box. What is required are longer arms to lift the bonnet/hood but are still able to fold in to the gap when closed

There was no way you could use the original hinge to get the result required because of the rotational angles it creates and the length of the arms.

I had a set of BMW hinges which worked in a similar fashion but allowed the hinge to lift the bonnet/hood up to 90 degrees so I studied they way they worked. They work with a ram rather than a spring and were almost flush fit so getting them to fit the Jaguar inner wing was a problem. I really wanted to keep the look of the Jaguar hinge if possible and use the spring which I will come to later rather than a modern hydraulic ram. I removed all the rivets holding the Jaguar hinge together and repeated this with the BWM hinge and to cut a long story short I used the mechanical arms of the BMW with the top plate and inner wing plate of the Jaguar to try and get a rotational hinge that worked.

I used a cardboard sheet to map the rotation of the hinges using different reference holes when the hinge plate was in place to get the right lift and rotation. You can see the difference between the original hing on the bottom and how I was able to lift the hing in the top diagram. I made an extra plate that bolted to the inner wing plate of the Jaguar out of ply board which allowed me to play around with different hole positions for the arms. A couple of days later and after lots of adjustment I thought I had the perfect set up and offered it up to the car. I made a template of the back edge of the bonnet/hood out of plastic which allowed me to use the hinge and see if I had all the correct heights and rotation then I fitted both hinges and the bonnet/hood. All seemed to work so I made the plate out of some 3mm steel I had lying around and then considered how I was going to fit the spring.

The thing with the spring on the original set up is that it allows the bonnet/hood to be lifted with assistance. The spring is stretched as the bonnet/hood is closed and contracts as it lifts but it also cleverly holds enough tension in the closed position to hold the back of the hinge down against the weather strip. I tried to fit the spring in the same orientation as the original but found two things. If it was not set correctly it would not hold the back edge of the bonnet down on the weather strip and if you got it slightly wrong the other way the back of the bonnet/hood would not lift when you opened the front edge up. I looked at using the hydraulic ram but with this in the correct position to push the bonnet/hood open it also tried to push the back edge up when the front was closed down. The ram was not going to work.

I am now working on a way of getting the spring to do as it should using levers attached to the levers. All very fiddly and possibly a lot easier to do these days on a 3D CAD program which I do not have rather than trial and error which is what I am using.

I am of the opinion at the moment that it would have been easier to have redesigned the heater box so the back could drop into the engine bay without fouling it than redesign the hinge.

Still working on it along with other things but the way it looks at the moment I would defy anyone to try and copy what I have done so far.

Rob.C. P1B8973BW

1968 S Type 3.4 Auto. Old English White.

1993 Yamaha FJ1200 Yellow

1966 Ford Anglia 1760 cross flow (still being built)

2012 Old English sheep dog. Grey and white.

http://torbayweddingcarclub.co.uk/?page_id=57

1968 S Type 3.4 Auto. Old English White.

1993 Yamaha FJ1200 Yellow

1966 Ford Anglia 1760 cross flow (still being built)

2012 Old English sheep dog. Grey and white.

http://torbayweddingcarclub.co.uk/?page_id=57

- Glyn Ruck

- Posts: 1619

- Joined: Sun Oct 07, 2018 2:14 pm

- Location: Llandudno, Cape Town, South Africa

- Contact:

Re: Bonnet hinge modification

Rob ~ I truly admire your efforts. I gave the issue some thought & it ended up in the too difficult basket without CAD.

1965 Jaguar 3.8 S Type, Sync4, OD, PAS, BRG/Biscuit on chrome wires.

http://www.jagstyperegister.com/forum_n ... ?f=3&t=152

A1B56966DN

http://www.jagstyperegister.com/forum_n ... ?f=3&t=152

A1B56966DN

Last 100 Members Who Visited This Topic. Total 227 visits

![]() NigelW (3),

NigelW (3), ![]() Fonzie (4),

Fonzie (4), ![]() DevilDog (15),

DevilDog (15), ![]() cass3958 (47),

cass3958 (47), ![]() Treetrimmer (9),

Treetrimmer (9), ![]() John Quilter (35),

John Quilter (35), ![]() Glyn Ruck (47),

Glyn Ruck (47), ![]() johngosnell (3),

johngosnell (3), ![]() HG_S-type (1),

HG_S-type (1), ![]() JCS (41),

JCS (41), ![]() RollyTG (2),

RollyTG (2), ![]() Orlando St.R (2),

Orlando St.R (2), ![]() Albion (1),

Albion (1), ![]() vaultsman (1),

vaultsman (1), ![]() Tom Hoffman (2),

Tom Hoffman (2), ![]() Jose (13),

Jose (13), ![]() maurizio ortodossi (1)

maurizio ortodossi (1)

Who is online

Users browsing this forum: No registered users and 1 guest