Page 1 of 2

Exhaust system

Posted: Thu Feb 13, 2020 2:26 pm

by RollyTG

Folks I need some feedback. My car has a good looking exhaust (stainless I think) but I find that it is an all-welded, one-piece unit. This is clearly not normal and, I suspect, will be an almighty PITA to remove at some point. Thoughts???

Re: Exhaust system

Posted: Thu Feb 13, 2020 2:49 pm

by Glyn Ruck

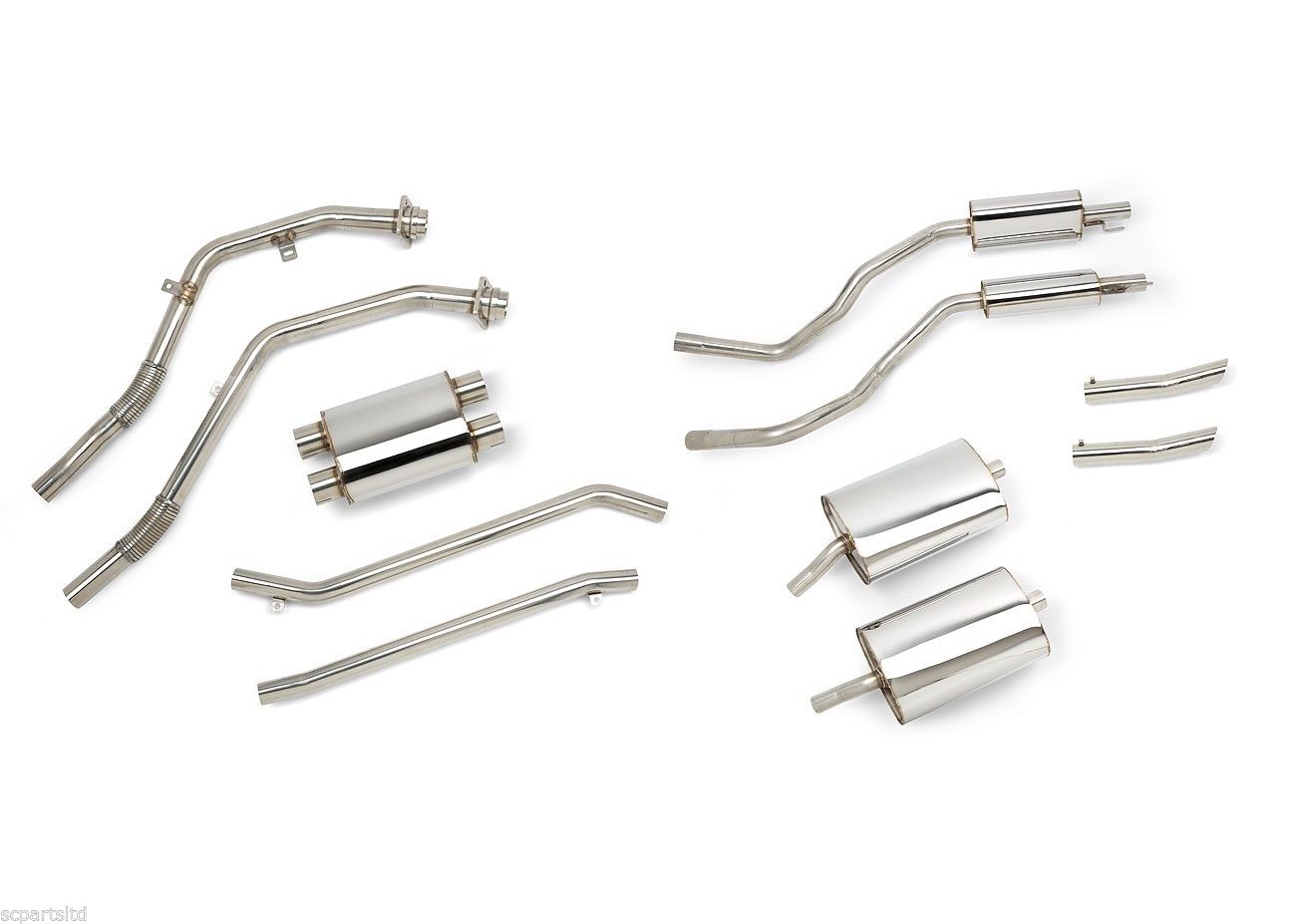

I have a Bell stainless system on mine. But all correct & separate with a proper stainless clamping kit.

Why do you need to remove it?

If it has to come off go to a sensible exhaust shop & get them to cut it off at sensible points so as to make it easy to weld back on & align.

- Exhaust.jpg (59.61 KiB) Viewed 3146 times

- Exhaust clamp 17 in diagram.JPG (74.92 KiB) Viewed 3146 times

Re: Exhaust system

Posted: Thu Feb 13, 2020 3:42 pm

by RollyTG

Thanks Glyn. Mine looks nothing like that. I will need to remove it to get at the auto transmission and later to take out the rear suspension unit for overhaul. It will definitely have to be cut to get it out. It also has only two small "silencers", so I'm thinking that will be an issue as well. A whole new system might be my best option.

Re: Exhaust system

Posted: Thu Feb 13, 2020 4:11 pm

by cass3958

Where are you Rolly as you do not have a location in your personal details?

I bought a Stainless Steel system from a company called SS Exhausts in Collumpton, Devon, UK.

https://stainlesssteelexhausts.co.uk/ They are only a 35 mins drive from my house and my previous owner had already put two new rear sections from SS Exhausts on my car so it seemed sensible to replace the front from the same company so I knew it was going to fit. Very good service and the system fits very well.

What I did find though and this is a problem with all manufacturers is that when they put joins in the exhaust they flare out one side so the other can slide in. When they do this they also put two slits either side of the flared sections which do tend to leak. Only slightly but you get a little puffing noise coming from the joints. They also supply "U" bolts to clamp the system together which pinch the pieces together and cause untold headaches trying to get the sections apart if you ever want to do any work which involves removing the exhaust. I have now replaced all my "U" bolts with 1.75" 45mm - 3" Inch 76mm Stainless Steel Butt Joint Exhaust Band Coupler Clamps with a smear of exhaust past. All sealed up and very quiet now.

https://www.ebay.co.uk/itm/1-75-45mm-3- ... 2749.l2649

If you wanted to keep the system you have got you could try cutting the pipes where you feel it would be best for removing and then using the above clamps to join the system back together. These clamps are designed to butt join the two ends together.

Re: Exhaust system

Posted: Thu Feb 13, 2020 6:59 pm

by RollyTG

Thanks Rob. The joining pieces looks just like what I will need. I am in South Carolina - just added that to my profile. I can probably get the same thing here. When I get it started I will be able to assess the noise level - it may be too loud for my liking.

Re: Exhaust system

Posted: Thu Feb 13, 2020 7:44 pm

by Glyn Ruck

I used this stainless clamp kit that does not distort the pipes. No leaks at all.

- 5b0a509e-cc11-4fc8-878b-1402bdd40eab.png (106.6 KiB) Viewed 3127 times

These things are a disaster.

- ee13d1a0-6209-4e8b-9b2c-bcffc58299be.png (118.88 KiB) Viewed 3127 times

Re: Exhaust system

Posted: Sat Feb 15, 2020 11:45 am

by JCS

Rolly

The advice already offered on using band clamps on stainless pipes is wise advice. I would suggest you do not use “U” bolt clamps, they work on mild steel pipe but not stainless, as stainless lacks ductility.

The stainless band clamps are not designed for butt joints and I think you will be better served by using straight stainless pipe sleeves about 8 inch (200mm) long across your joints. This of course is only appropriate if you are cutting up a fully welded system ready for refitting. These sleeves are better position over the outside of the pipes, but can be used as internal sleeves if required. In some locations it can be advantageous to weld, or tack weld an internal sleeve in the end of one of the pipes, in particular when the joint is close up against a silencer or mounting.

If you are going to split up a previously welded system it is worthwhile studying where the ex-factory system is jointed. The sectioning immediately to the rear of the main silencers can be improved a little. On some systems the mounting onto the rear sub frame can cause a removal issue. This occurs when the complete mounting can be removed from the subframe but the stub bar on the silencer will not allow the rear end of the silencer to lower. In essence the main silencers need moving forward for removal more than the existing set up allows. I think an external sleeve and joint forward of the main silencer front mounting would allow that extra travel.

If you fit a new standard system you will understandably not have to bother with splitting the system but a little care in positioning the main silencers as far forward as possible will pay dividends later. Sometimes it is advantageous to be able to remove a silencer quickly without having to remove the tail pipes and resonator boxes.

Another suggestion is to permanently mark the adjacent joint positions so that the exhaust sections can be quickly and correctly aligned. I use grinding marks at each joint.

You will find that most of the replacement stainless systems are poorly welded with the wrong filler wire and MIG, not TIG welding. If you purchase a new system it might be worthwhile cleaning and painting the welded joint.

Re: Exhaust system

Posted: Sat Feb 15, 2020 3:24 pm

by RollyTG

Thanks for all that. Could you just clarify what you n=mean by "stub bar" on the silencer?

Re: Exhaust system

Posted: Sat Feb 15, 2020 6:17 pm

by JCS

Rolly

If you view Glyn’s image above, which, is taken from the parts manual you will see the main silencers numbers 14 and 15 are located by the mountings number 16. There is a spike or stub attached to the rear of both silencers and that enters the mounting, this is what I referred to as a “stub”.

Sorry for any confusion.

Norman

Re: Exhaust system

Posted: Sun Feb 16, 2020 1:00 am

by John Quilter

I think if I were trying to do this I would check with my local muffler shop and see what variety of connecting sleeves they have in stock. If one can be found to have the same inside diameter as the outside of your existing pipe and a proper length I would use these and apply some exhaust system sealant to prevent leaks. Cutting items 6 and 7 on the factory diagram in the middle would allow the main rear silencers to slide forward and be removed and the two inlet/two outlet silencer to slide backward for removal.